HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine

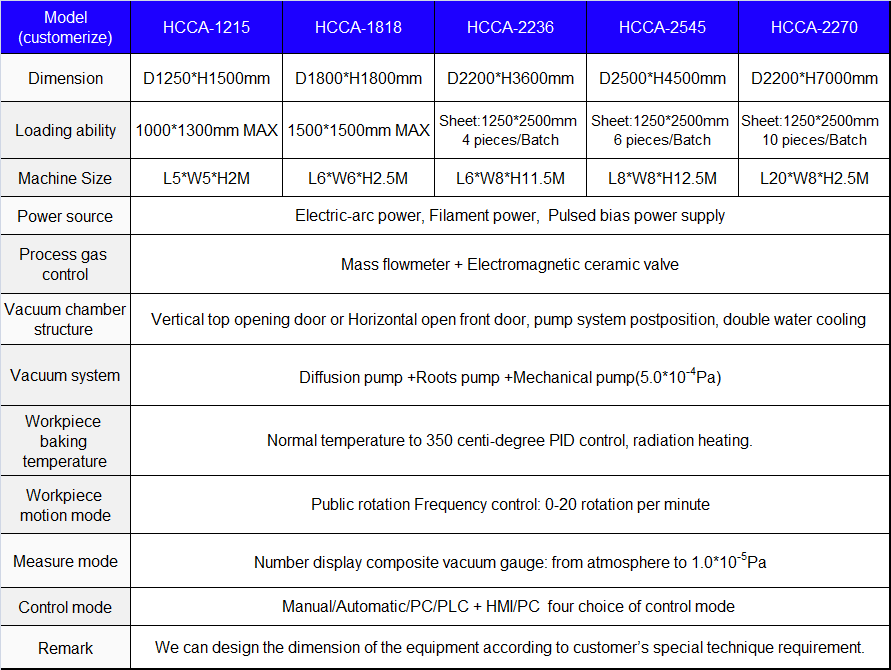

HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine Specification

- Product Type

- PVD Vacuum Plating Machine

- General Use

- Stainless Steel Furniture Coating

- Material

- Stainless Steel (SUS304/316 recommended)

- Type

- Big Size

- Weight (kg)

- Approx. 12000

- Coating Speed

- 15 m/min (Adjustable)

- Coating Head

- Magnetron Sputtering / Arc Evaporation

- Coating Width

- Up to 1500 mm

- Coating Material

- Titanium, Zirconium, Gold, etc.

- Computerized

- Yes

- Automatic

- Fully Automatic

- Control System

- PLC Touch Screen

- Power Source

- Electric

- Power Consumption

- 150 KW

- Heating System

- Electric Resistance Heating

- Drive Type

- Automatic

- Voltage

- 380V/50Hz (Three Phase)

- Rewinder Type

- Automatic

- Unwinder Type

- Heavy Duty Manual/Automatic

- Rewinding Width

- Up to 1500 mm

- Unwinding Width

- Up to 1500 mm

- Dimension (L*W*H)

- 7000 x 3500 x 3600 mm

- Feature

- Large Capacity, High Uniformity Layer, High Efficiency

- Color

- Gold / Customizable

- Plating Color Options

- Gold, Rose Gold, Silver, Black, Bronze, etc.

- Cycle Time

- 4590 min per batch (depending on process)

- Applicable Substrates

- Metal, Glass, Ceramic, Plastic

- Process Type

- Physical Vapor Deposition (PVD)

- Cooling System

- Water Cooling

- Max Substrate Size

- Up to 1800 x 1500 mm

- Safety Features

- Overheat, Overpressure, Power Backup, Emergency Stop

- Chamber Material

- Stainless Steel

- Vacuum Pressure

- 5.0 x 10 Pa or better

- Coating Layer Thickness

- 0.11.2 m (Adjustable)

HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine Trade Information

- Minimum Order Quantity

- 1 , , Set

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 60 Days

- Packaging Details

- wooden package

- Main Export Market(s)

- Western Europe, Middle East, Africa, North America, Central America, Australia, South America, Asia, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine

The machine can get all kinds of color on stainless steel products,we can make machine Diameter from 800mm until 3300mm, height from 800mm until 7200mm, it suitable for coating all small parts,stainless steel sheet, stainless steel pipe,stainless steel counter,stainless steel connection.sainless steel chair. In China. 95% of stainless steel market are using our machine to decorative coating. We already exporting this machine to German,England,Iran,India,Vietnam,Korea,Thailand,Indonesia,singapore,Malaysia,Turkey,Dubai,Egypt,Uzbekistan, ect.

We can do tunrkey project for customers: Including 8K mirror line, hairline, No. 4, etching line, PVD, anti-finger coating and plastic lamintor line.

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C,O) and DLC

Stainless steel sheets size(2 pieces per cycle,3 pieces per cycle,4 pieces per cycle,6 Pieces per cycle)

Stainless steel Accessories,Including Stair,Hotel trolley,chair,table,Dishes,spoons,bowls,coffee cup,teapot and others,Biggest size can load Daimeter2000*Height3500mm

is designed for stainless steel sheet to get a decorative coating by ion plating technique, the ion plating layer has a real metal texture, which is much different from chemical coating.It is an ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate , great ionization rate, big ion energy,easy operation, low cost, large productive capacity, etc.

Characteristic: The principle of the electric arc is integrating cold cathode arc discharge self-sustained light unite pulse technique and magnetron sputtering technology, thinning the particles to improve the properties of the film. It can coat on the surface of the metal as well as nonmetal.

Applied industry: It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film, and in a very short time to complete all the machining process, it is a highly efficient multi-functional ion coating equipment.This machine is extensively used in the fields of ultra-hard coating about the tools and mould, decorative coating about stainless steel plate,car wheels, ceramics, golf, watches making, hotel product, sanitary ware, luminaires, optical frame, hardware, etc .

The chamber diameter of this series is 1800-3300mm, and height is 3000-7000mm,it can coat three sheets that size is 1500X4000mm;with three sets of large power vacuum pumping systems, high pumping speed,short cycle time, with 21-56 pieces of roud arc target, they are installed reasonable, at the same time,equipment is equipped with pulsed bias system, which make the adhesion of coating strong,color of coating uniform.

Touch screen+PLC control achieved full automatic of equipment, manual and auto can be switched any time, this make machine reliable and easy operation.

The colors of this equipment can do are gold,silver,brown,black,rose gold,coffee,raibow and blue etc decorative coatings, and it's widely used in metals,furniture,lights,hardware,car parts and aircrafts etc, all performances of equipment have reached international advanced level and have exported to European and American countries.

Advanced PVD Technology for Superior Finishes

Employing magnetron sputtering and arc evaporation, the HCVAC machine delivers highly uniform, durable coatings with customizable colors. The adjustable coating layer (0.11.2 m) and high coating efficiency ensure outstanding results for both decorative and protective applications across various substrates.

Efficiency and Safety in Large-Scale Production

With a fully automated PLC touch screen control and safety features such as overheat, overpressure, and emergency stop, the HCVAC PVD machine prioritizes operation safety and reliability. Fast cycle times, high coating speed, and robust construction enable seamless, large-batch processing for busy manufacturing environments.

Versatile Substrate Handling and Customization

Capable of coating stainless steel, metal, glass, ceramic, and plastic components, this system is suitable for wide-ranging industries. Users can select plating colors and customize coating width, maximizing production flexibility and aesthetic options for their finished products.

FAQs of HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine:

Q: How does the HCVAC Big Size Stainless Steel Furniture Gold PVD Vacuum Plating Machine operate?

A: This machine uses Physical Vapor Deposition (PVD) processesmagnetron sputtering and arc evaporationwithin a controlled vacuum chamber to deposit thin metallic layers onto substrates. Operators control all parameters via an intuitive PLC touch screen system for precise and repeatable coatings.Q: What is the typical process cycle time for this plating machine?

A: A standard batch takes between 45 and 90 minutes to complete, depending on factors such as coating thickness, chosen material, and process requirements. This fast cycle enables efficient production for large quantities.Q: When should I use this machine for furniture coating?

A: This equipment is ideal when you require high-quality, uniform metallic or decorative finishes on stainless steel furniture components or similar substrates. It is especially well-suited for large-sized panels or items that need consistent color and durability.Q: Where can the machine be installed and who is it suitable for?

A: Due to its size and power requirements (7000 x 3500 x 3600 mm; 380V/50Hz, three-phase), the machine is best installed in manufacturing plants or coating workshops with adequate infrastructure. It is suitable for distributors, exporters, manufacturers, suppliers, and traders in need of advanced surface finishing technology.Q: What kinds of substrates and colors can be coated?

A: The machine accommodates a broad range of substrates including metal, glass, ceramic, and certain plastics. Available coating colors include gold, rose gold, silver, black, bronze, and others, with thickness and color options fully customizable.Q: What benefits does this PVD machine offer over conventional plating methods?

A: PVD technology provides strong adhesion, high wear resistance, and superior aesthetics with environmentally friendly processes. Its uniform coating and adjustable thickness boost product quality and extend the life and appeal of coated furniture or components.Q: How is safety ensured during operation?

A: Safety features include overheat and overpressure detection, power backup, and an emergency stop function. These measures protect operators and equipment, reducing the risk of accidents and ensuring consistent, reliable production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Multi Arc Ion Vaccum Coating Machine Category

HCVAC Stainless Steel Sheet Gold Black Blue Rosegold Color PVD Coating System

Price 150000-600000 USD ($) / Set

Minimum Order Quantity : 1 Container

Control System : PLC Control

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Warranty : One year warranty, lifetime maintenance

Computerized : Yes

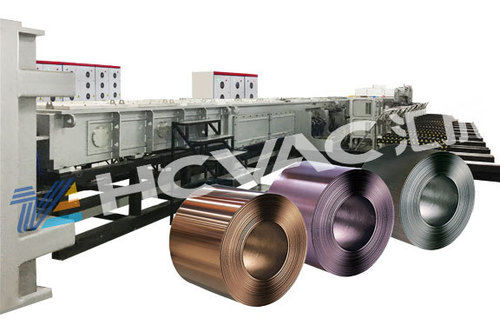

HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip

Price 400000-5000000 USD ($) / Set

Minimum Order Quantity : 1 Container

Control System : PLC Control

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Warranty : One year warranty, lifetime maintenance

Computerized : Yes

HCVAC Glass Cup Brass Gold PVD Magnetron Sputtering Coating Machine

Price 100000-500000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Color : Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

Warranty : One year warranty, lifetime maintenance

Computerized : Yes

HCVAC Optical Hard Coating Machine / High Vacuum Coating System for Optical Ar Film Coating

Price 150000-800000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Warranty : One year warranty, lifetime maintenance

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free