HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment

Price 150000-500000 USD ($)/ Set

HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment Specification

- Product Type

- PVD Vacuum coating machine

- Material

- Stainless Steel

- Type

- Metal Coating Machine, Industrial Coating Machine

- Weight (kg)

- 5-8 Tonne

- Coating Head

- Other

- Coating Material

- Other

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Power Consumption

- 45-150KW

- Voltage

- 380V

- Dimension (L*W*H)

- customized

- Feature

- Coating

- Color

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- Warranty

- One year warranty, lifetime maintenance

HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- FOB SHENZHEN

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Delivery Time

- 60 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Package or carton package

- Main Export Market(s)

- Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment

HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment

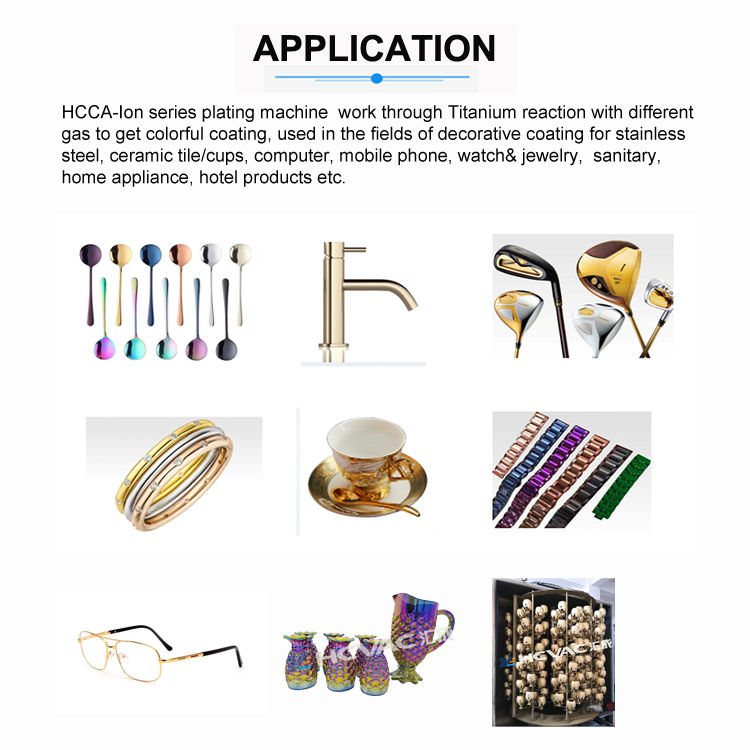

The machine is mainly design for sanitary ware/bathroom fitting parts. Its equipped with several big size electrical arc evaporation sources and magnetron sputtering coating system, to deposit high performance metal decorative film on brass, zinc alloy, stainless steel, plastic and other metal parts surface. It can get all types of metal color series on substrate. The coating film includes TiN, Zr,T iCN, ZrCN, CrN, CrCN, brass, bronze, chrome etc. Color series includes AF, SN, BN, VF, BV, G, BX, TB, AF, SN, 96CB, CB, TXB, VS, S, BS, BRZ, BGD, PGD and so on. It can get different colors by adjusting coating technics. It is largely used in the sanitary ware/ Kitchen ware field.

Benefits of PVD

Increase life span of the PVD coated products

Corrosion resistance

Chemical resistance

Wear resistance

Friction resistance

Superior Decorative finish

Uniform coating

Low maintenance cost

Environment friendly

Will not tarnish / fade

Re coating possible at a high quality level

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

Technical parameters:

FAQs of HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment:

Q: What is the warranty for the HCVAC Brass Zinc Alloy Faucet Tap Chrome Gold Plating Machine Pvd Coating Equipment?

A: The machine comes with a one year warranty and lifetime maintenance.Q: Is the machine automatic?

A: Yes, the machine is automatic.Q: What type of control system does the machine have?

A: The machine has a PLC control system.Q: Is the machine computerized?

A: Yes, the machine is computerized.Q: What is the power consumption of the machine?

A: The power consumption ranges from 45-150KW.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Multi Arc Ion Vaccum Coating Machine Category

HCVAC Stainless Steel Furniture Table Leg Chair Decorative PVD Vacuum Coating Machine

Price 150000-300000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Product Type : PVD Vacuum coating machine

Type : Metal Coating Machine, Industrial Coating Machine

Automatic : Yes

HCVAC Golden Stainless Steel Furniture Titanium PVD Coating Machine

Price 120000-500000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Product Type : PVD Vacuum coating machine

Type : Industrial Coating Machine, Metal Coating Machine

Automatic : Yes

HCVAC Stainless Steel Flatware Plate Gold PVD Vacuum Coating Equipment

Price 120000-500000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Product Type : PVD Vacuum coating machine

Type : Metal Coating Machine, Industrial Coating Machine

Automatic : Yes

HCVAC Furniture Handles, Knobs, Screws, Bolts PVD Vacuum Coating Machine

Price 150000 USD ($) / Set

Minimum Order Quantity : 1 Set

Control System : PLC Control

Product Type : Coating Production Line

Type : Industrial Coating Machine, Metal Coating Machine

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry