HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant

HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant Specification

- Product Type

- Sanitaryware Decoration

- General Use

- Sanitaryware Decoration

- Material

- Stainless Steel

- Type

- Industrial Coating Machine, Metal Coating Machine

- Weight (kg)

- 5-8 Tonne

- Coating Width

- 1250*1500mm, 1400*1600mm, 1600*1800mm Millimeter (mm)

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Power Source

- Electric

- Heating System

- Electric

- Dimension (L*W*H)

- 1250*1500mm, 1400*1600mm, 1600*1800mm Millimeter (mm)

- Feature

- High Precision, Coating

- Color

- Gold, Silver, Rose Gold, Black, Blue and So on

- Warranty

- One year warranty, lifetime maintenance

HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant Trade Information

- Minimum Order Quantity

- 1 Container

- FOB Port

- FOB shenzhen

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 60 Days

- Packaging Details

- Wooden Package or carton package

- Main Export Market(s)

- Asia, Eastern Europe, Middle East, North America, South America, Australia, Central America, Western Europe, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant

HCVAC Sanitary ware decoration PVD Titanium vacuum coating machine,plant

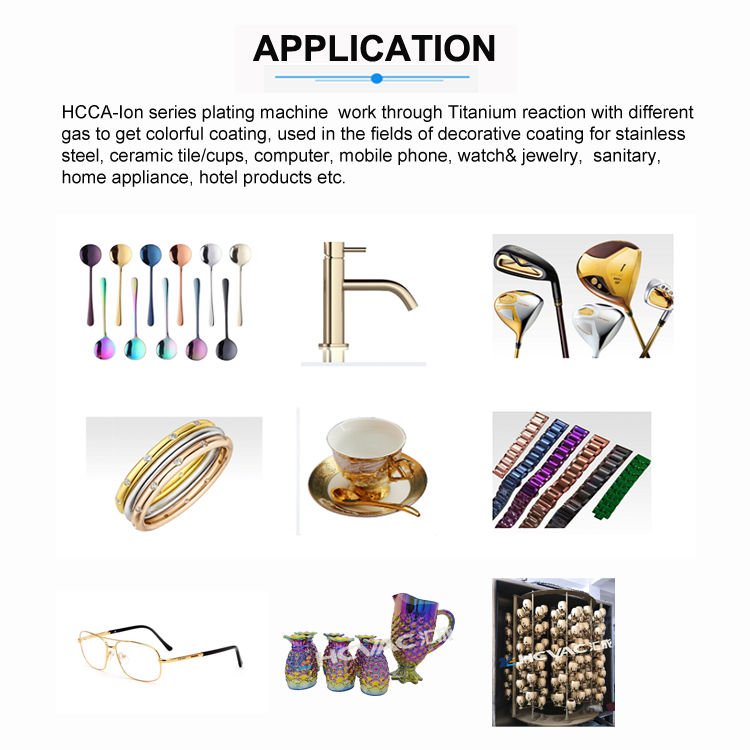

The machine use low temperature deposition coating technology to get all kinds of color coating on sanitaryware products,it is totally different with the traditional electroplating way. the coating which get by PVD can provide you excellent coating,strong adhesion and finess coating. the color series including Chrome,gold,shinning Zr,TiN,Rosegold,black and jet black and other color series. we service USA KOHLER.Moen,Delta and other famouse companies for the coating project.

This machine mainly integrates the technology of MF magnetron sputtering and electric arc ion evaporation, combining the ion source and the pulse bias voltage. It is full automation control when coating films.

Applied industry: It is widely used in the sanitary ware, watchband, watchcase, mobile shell, hardware, tableware, etc. It can coat TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3 and other decorative films.

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are continuously monitored and controlled by the on-board computer software.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

Technical parameters

| Mode Dimension | JTL-900 | JTL-1100 | JTL-1250 |

| 900*1000mm | 1100*1000mm | 1250*1100mm | |

| Coating mode and main confirguration | Six multi-arc targets + one set of column targets + one set of plane rectangle magnetron sputtering targets | Six multi-arc targets + a pair of twin (MF)magnetron sputtering targets | Twelve multi-arc targets + two sets of plane rectangle magnetron sputtering targets+ a pair of twin (MF)magnetron sputtering targets |

| Power source | Electric arc power, DC magnetron power, MF magnetron power, filament power, pulse power, linear ionized source. | ||

| Process gas control | Quality flowmeter + electromagnetism ceramic valve | ||

| Vacuum chamber structure | Vertical single(side) door, pump system postposition, double water-cooling | ||

| Vacuum system | Molecule pump +Roots pump +Mechanical pump(5.0*10 -5 Pa) Diffusion pump +Roots pump +Mechanical pump(5.0*10 -4 Pa) | ||

| Work piece baking temperature | Normal temperature to 350 centi-degree PID control, radiation heating. | ||

| Work piece motion mode | Public rotation Frequency control: 0-20 rotation per minute | ||

| Measure mode | Number display composite vacuum gauge: from atmosphere to 1.0*10 -5 Pa | ||

| Control mode | Manual/Automatic/PC/PLC + HMI/PC four choice of control mode | ||

| Remark | We can design the dimension of the equipment according to customers special technique requirement. | ||

FAQs of HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant:

Q: What is the weight of the HCVAC Sanitaryware Decoration Color PVD Titanium Vacuum Coating Machine/Plant?

A: The weight of the machine is 5-8 Tonne.Q: What type of coating does this machine perform?

A: This machine is an Industrial Coating Machine used for Metal Coating and General Use in Sanitaryware Decoration.Q: What are the dimensions of the machine?

A: The dimensions are 1250*1500mm, 1400*1600mm, 1600*1800mm.Q: What material is the machine made of?

A: The machine is made of Stainless Steel.Q: Does the machine have a warranty?

A: Yes, it comes with a one year warranty and lifetime maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Kitchen & Bath PVD coating machine Category

HCVAC Stainless steel sheet PVD coating machine

Price Range 100000.00 - 500000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Warranty : 1 year

Color : silver, golden, rose gold, grey, blue, coffee, bronze, black,rainbow etc.

General Use : surface coating

Product Type : PVD Vacuum coating machine

HCVAC Stainless Steel Utensil/Cookware PVD Titanium Coating Machine

Price Range 100000.00 - 500000.00 USD ($) / Set

Minimum Order Quantity : 1 Container

Warranty : One year warranty, lifetime maintenance

Color : Gold, Silver, Rose Gold, Black, Blue and So on

General Use : decorative coating color in Stainless steel spoon,forks,knifes,flatware,kitech sinks,kitech doors,stoves and other related products

Product Type : decorative coating color in Stainless steel spoon,forks,knifes,flatware,kitech sinks,kitech doors,stoves and other related products

Ultra Low Temperature Deposition Equipment

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Color : Silver

General Use : Industrial

Product Type : Low Temperature Deposition Equipment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free