HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment

HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment Specification

- Product Type

- PVD Vacuum coating machine

- General Use

- Metal strip includes stainless steel coil, brass coil, phosphor copper coil, aluminum coil;

- Material

- Stainless Steel

- Type

- Industrial Coating Machine, Metal Coating Machine

- Coating Head

- Other

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Humidification System

- Yes

- Feature

- Coating, Low Energy Consumption, High Speed, High Precision

- Color

- Gold, Silver, Rose Gold, Black, Blue and So on

- Warranty

- One year warranty, lifetime maintenance

HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- FOB SHENZHEN

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 60 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Package or carton package

- Main Export Market(s)

- Eastern Europe, Middle East, South America, Central America, North America, Australia, Western Europe, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment

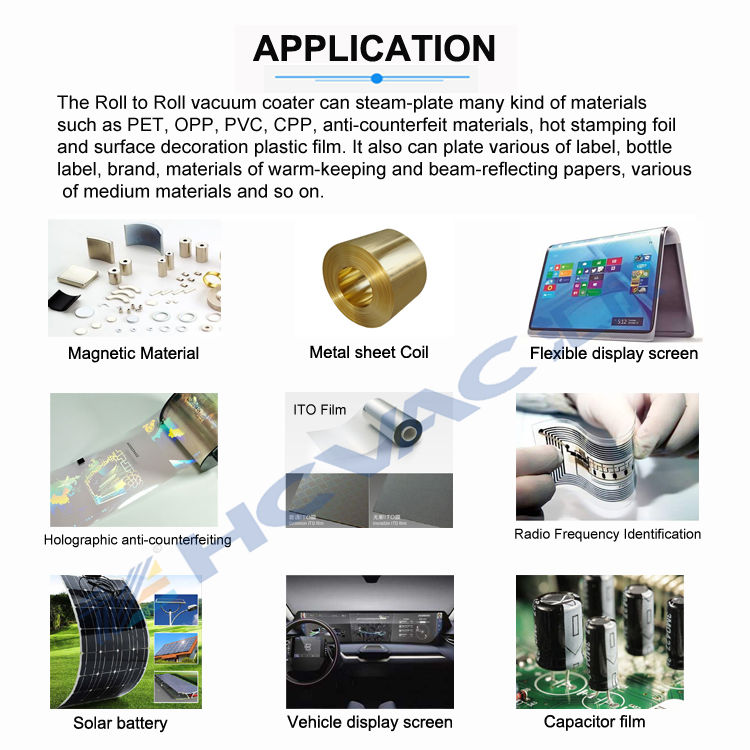

Applications:

*Metal strip includes stainless steel coil, brass coil, phosphor copper coil, aluminum coil;

*ITO film, flexible printed circuit board (FPCB), Low-E or intelligent glass, flexible and wearable electronic products, display, touch screen, sensor, RFID tag, LED lighting;

*Intelligent packaging, packaging materials like PET, (B) OPP, PVC, CPP and other macromolecular films, metal foil, paper, decoration materials, textile, fabric;

*Power battery, super capacitor, semiconductor, solar electrode battery, etc.

*Anticorrosive film coating, Decorative film coating, High resistance film coating, Transparent conductive layer, Reservoir layer, Sensor layer coating, Conductive metal coating, Electrochromism coating etc.

Features:

*Minimum particle generation

*Intelligent and robust design, easy to maintain and clean, long normal operation time of the machine

*Powerful plasma pretreatment with high product consistency and performance

*Scratch and wrinkle free winding (closed-loop tension control)

*Superior productivity, high system versatility and flexibility

*Compact design, minimum floor space

*Many upgrade options

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Easy to implement

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

FAQs of HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment:

Q: What is the power consumption of the HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment?

A: The power consumption of the equipment ranges from 90KW to 300KW.Q: What is the voltage requirement for the equipment?

A: The voltage requirement for the equipment is 380V.Q: What type of material is used in the construction of the equipment?

A: The equipment is made of stainless steel.Q: What are the general uses of this equipment?

A: The equipment is commonly used for coating metal strips including stainless steel coil, brass coil, phosphor copper coil, and aluminum coil.Q: Does the equipment have a warranty?

A: Yes, the equipment comes with a one year warranty and lifetime maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roll To Roll Web vacuum coating system Category

HCVAC Suspension Roll To Roll Vacuum Coating Machine

Price Range 300000.00 - 1200000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : Standard (customizable)

Material : Other, Stainless steel structure

Automatic : Yes

HCVAC ITO Azo Roll to Roll Thin Film Web Coating Machine for Solar Cell, Touch Screen

Price 300000-1200000 USD ($) / Set

Price Range 250000.00 - 600000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Material : Stainless Steel

Automatic : Yes

HCVAC roll-to-roll sputter systems for conductive layer

Price 300000 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Material : Stainless Steel

Automatic : Yes

PVD Metal Coating Systems for Metal Strip Metal Sheet Metal Coil

Price 300000 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : Gold, Silver, Rose Gold, Black, Blue and So on

Material : Stainless Steel

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free