HCVAC Suspension Roll To Roll Vacuum Coating Machine

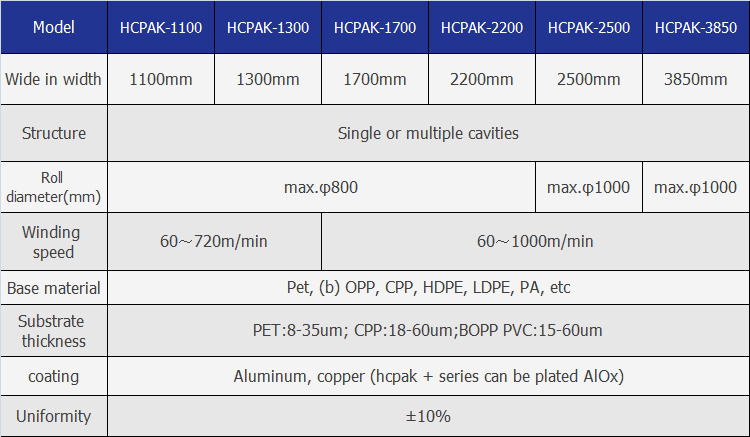

HCVAC Suspension Roll To Roll Vacuum Coating Machine Specification

- Product Type

- Suspension roll to roll vacuum coater

- General Use

- Industrial vacuum coating for films, plastics, metals

- Material

- Stainless steel structure

- Type

- Roll to Roll Vacuum Coating Machine

- Weight (kg)

- Approx. 12000

- Coating Speed

- 10-120 m/min (adjustable)

- Coating Head

- Magnetron sputtering / evaporation source

- Coating Width

- Customizable, up to 2100 mm

- Coating Material

- Aluminum, Copper, Alloy, ITO, etc.

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC with touchscreen HMI

- Power Source

- Electric

- Power Consumption

- 120-300 kW (depending on configuration)

- Heating System

- Electric heating / Infrared (customizable)

- Drive Type

- Servo motor drive

- Voltage

- 380V/50Hz (customizable)

- Humidification System

- Not Included

- Glue Type

- No glue (vacuum deposition)

- Rewinder Type

- Automatic tension control rewinder

- Unwinder Type

- Shaftless hydraulic unwinder

- Rewinding Width

- Maximum 2100 mm

- Unwinding Width

- Maximum 2100 mm

- Dimension (L*W*H)

- 11000*4200*3400 mm

- Feature

- High automation, uniform coating, high efficiency

- Color

- Standard (customizable)

- Substrate Thickness Range

- 8-250 m

- Film Uniformity

- 2% across web width

- Operator Interface

- Touchscreen/color display

- Max Coating Thickness

- Adjustable as per process requirement

- Service Support

- Onsite installation and training available

- Operation Environment

- Cleanroom, dust-free

- Deposition Rate

- Up to 600 nm/min (material dependent)

- Noise Level

- <80 dB

- Chamber Material

- High strength stainless steel

- Working Temperature

- 5C - 40C

- Vacuum System

- Roots pump, Rotary vane pump, Diffusion pump or Turbomolecular pump

- Cooling System

- Water cooling

- Safety Feature

- Multiple interlocks with alarm system

- Process Gas

- Argon, Oxygen, Nitrogen (as per coating material)

- Max Roll Diameter

- 800 mm

- Loading/Unloading

- Automatic

- Web Tension Control

- Automatic closed-loop control

HCVAC Suspension Roll To Roll Vacuum Coating Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- shenzhen

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- Delivery Time

- 60 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden package

- Main Export Market(s)

- Western Europe, Middle East, Africa, Australia, North America, Central America, South America, Asia, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About HCVAC Suspension Roll To Roll Vacuum Coating Machine

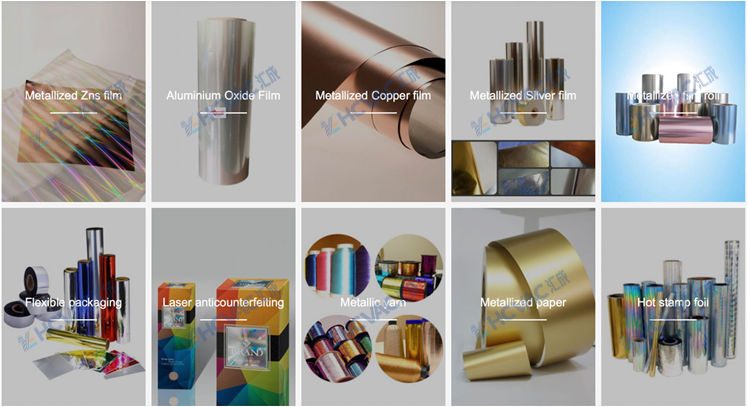

Traditional aluminum coatings are deposited on a wide range of flexible substrates to enhance optical, protective and barrier properties. The hcpak series covers a width of 1100-3850mm, as well as all common plastic film and paper substrates. The maximum output is achieved at different speeds for the substrate with a width of more than 2500 mm, and the processing speed is increased by more than 25% compared with the traditional system.

In addition to the measurable layer uniformity over the substrate width, the innovative evaporator arrangement and gas distribution provide significant results in the visible range, which are important for special optical applications.

Especially when it comes to flexibility, the hcpak + series sets the benchmark, and even if the system is primarily used for alumina coatings.

We can design the whole system according to customer's requirements.

Advanced Vacuum Coating for Industrial Films

This machine is engineered to provide consistent, high-quality coatings across a variety of substrates, including plastics, metals, and specialized films. With adjustable parameters for coating thickness and speed, it delivers unparalleled flexibility for different process requirements. Its robust stainless steel chamber ensures durability and corrosion resistance, while automatic web tension control maintains optimal film handling and uniformity.

Fully Automated Operation and Control

Equipped with an intuitive PLC-based touchscreen interface, the HCVAC Roll To Roll Vacuum Coating Machine enables precise management of process conditions and real-time monitoring. Key features such as automatic loading/unloading, shaftless hydraulic unwinding, and servo drive control contribute to seamless operation and enhance productivity. Multiple interlocks and alarm systems safeguard operational safety in cleanroom environments.

Customizable Coating Solutions for Diverse Materials

Suitable for coating a wide range of materialsincluding aluminum, copper, alloy, and ITOthe machine utilizes magnetron sputtering or evaporation sources. The cooling system ensures stable operation, while water cooling preserves film integrity. Coating widths, chamber dimensions, and heating methods are customizable to meet specific industrial needs and production lines.

FAQs of HCVAC Suspension Roll To Roll Vacuum Coating Machine:

Q: How does the HCVAC Suspension Roll To Roll Vacuum Coating Machine achieve precise film uniformity?

A: The machine utilizes automatic closed-loop web tension control combined with advanced vacuum deposition sources, maintaining uniform coating thickness within 2% across the web width. Continuous monitoring and servo motor drives help ensure each film layer is evenly deposited.Q: What types of materials can be coated using this vacuum coating machine?

A: This system can coat a broad selection of materials, including aluminum, copper, various alloys, ITO, and more. Depending on process requirements, the equipment accommodates both metallic and non-metallic films, plastics, and substrates of varying thickness (8-250 m).Q: When is it recommended to use water cooling in the coating process?

A: Water cooling is critical during high-power or extended coating sessions, as it prevents overheating of both the vacuum chamber and substrate, ensuring stable deposition rates and protecting film quality throughout the process.Q: Where is the machine typically installed and operated?

A: The machine is designed for cleanroom, dust-free industrial environments where controlled conditions are essential. Installation and onsite training support are provided by the manufacturer for distributor, supplier, and manufacturer use.Q: What is the coating process utilized by this equipment?

A: The HCVAC machine applies coatings via magnetron sputtering or evaporation sources inside a high-vacuum chamber, using process gases such as argon, oxygen, or nitrogen. Coating thickness and deposition rate can be tailored to the applications requirements, using computerized PLC control for precision.Q: How does the automatic loading and unloading system benefit operations?

A: Automatic loading/unloading minimizes manual intervention, reduces the risk of contamination, and enhances throughput. This streamlining results in faster turnaround times and improved operator safety within the production workflow.Q: What are the main advantages of using the HCVAC Roll To Roll Vacuum Coating Machine?

A: Key benefits include high automation, customizable coating parameters, exceptional repeatability, industrial-grade reliability, and service support. The system facilitates large-scale, efficient production while maintaining strict uniformity and quality standards, making it ideal for exporters and industrial suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roll To Roll Web vacuum coating system Category

HCVAC ITO Azo Roll to Roll Thin Film Web Coating Machine for Solar Cell, Touch Screen

Price 300000-1200000 USD ($) / Set

Price Range 250000.00 - 600000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Material : Stainless Steel

Type : Rotary Coating Machine, Industrial Coating Machine, Metal Coating Machine

HCVAC roll-to-roll sputter systems for conductive layer

Price 300000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Material : Stainless Steel

Type : Industrial Coating Machine, Metal Coating Machine

HCVAC Roll to Roll Magnetron Sputtering PVD Vacuum Coating Equipment

Price Range 350000.00 - 1200000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Material : Stainless Steel

Type : Industrial Coating Machine, Metal Coating Machine

PVD Metal Coating Systems for Metal Strip Metal Sheet Metal Coil

Price 300000 USD ($) / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Material : Stainless Steel

Type : Industrial Coating Machine, Metal Coating Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry